- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Size: | |

|---|---|

| Weight: | |

| Valves: | |

| Total prower: | |

| Availability: | |

| Quantity: | |

RO-1000L/H

KAIYUAN

8421219990

Product Description

optional),reverse osmosis membrane.

It can remove particle, colloid, organic impurity, heavy metal ion, bacteria, virus in water, and it can also remove 99% dissolved salt. The whole system desalination rate can reach 96%-99% to make permeated water conductivity<10 us/cm. Dense water also won’t polluted environment.

Reverse Osmosis equipment no need to consider about input water quality too much. And the main features of RO equipment is no need to do any regeneration, it can be keep stable for long time.

The second stage reverse osmosis system use the first stage reverse osmosis system output water as raw water to make water to be more pure. Normally output water conductivity<2 us/cm.

| 1.Capacity: 1000L/H 2. Rated power: 3KW/H 3. Voltage: 110V/220V/380V, 50Hz/60Hz, Single phase/3phase 4. Desalting rate:>=97% 5. Water recovery rate: 50-75% 6. Conductivity of raw water: TDS≤3000-5000PPM 7. Conductivity of pure water: TDS≤90-150PPM 8. Packing size: 1900*650*1850mm 9. Total weight: 600kg |

A. Regulating wheels B. PC Touch Screen/PLC C. PH adjustment anti-scale D. Automatic cleaning system E. Auto or manual control valve F. U-PVC or stainless steel pipe G. UV sterilizer/Ozone Generator H. Dosing system/Water Softener I PE or stainless steel raw/pure water tank J. FRP or stainless steel pre-treatment tank |  |

Process: raw water tank→ raw water pump→quartz sand filter →activated carbon filter→water softener/chemical dosing system(optional)→security filter→high pressure pump→RO system→pure water tank+UV sterilizer(ozone generator) +precision filter+water supply point

| Function of every part: | |

| Raw water pump | provide the pressure to quartz sand filter/active carbon filter/ water softener |

| Quartz Sand filter | get rid of turbidity, suspended matter |

| Active Carbon filter | Remove the color, free chloride, organic matter, harmful matter, ect. |

| Security filter | prevent large particles into RO membrane, accuracy is 5um |

| High pressure pump | Provide the high pressure to RO membrane |

| RO system | main part of the plant. The RO membrane's desalting rate can reach 97% and above, removing over 99% ions. |

Component:

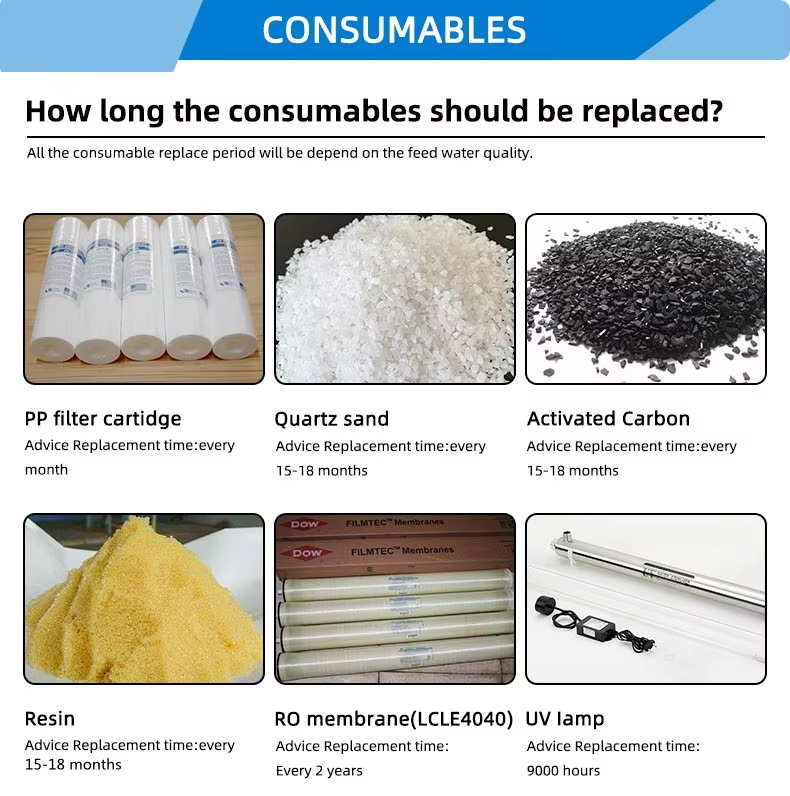

There are several kinds of consumables you need to replace regularly.

a. Quartz sand: replaced about every 15 months.

b. Activated carbon: replaced about every 15 months.

c. Resin: replaced about every 15 months.

d. PP Filter cartridge: replaced about every 1 month

e. Ro membrane: replaced about every 2 year

We suggest you buy 1- 2 years of PP filter cartridges together with machine. Because these PP filter cartridges need to replace every month.

FAQ

Q: What is the capacity of the KAI YUAN 1000 LPH Brackish Water Filter Machine?

A: The system processes up to 1000 liters per hour, providing a daily output of up to 20,000 liters, ideal for industrial and commercial uses.

Q: What impurities can this machine remove from brackish water?

A: Using advanced Reverse Osmosis (RO) technology, this machine effectively removes salts, heavy metals, organic compounds, and other impurities, producing high-quality drinking water.

Q: Can this system be customized?

A: Yes, it can be tailored with additional filtration stages, pre-treatment options, and post-treatment modules to meet specific needs.

Q: What materials are used in the system?

A: Constructed with Fiberglass, for brackish water equipment, FRP material is more corrosion-resistant

Q: What maintenance is required?

A: The system has an automated control panel for easy monitoring. Regular maintenance includes replacing filters and membranes, with full support provided by the KAI YUAN team.

Company Introduction