- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Material: | |

|---|---|

| Availability: | |

| Quantity: | |

RO-6TPH

KAIYUAN

8421219990

Product Description

KAI YUAN 6000 LPH Factory Purifier System Brackish Water Filter

Machine Industrial Drinking Water Plant Treatment Equipment

| Different Water TDS Compare and Usage | ||||

| Bottled water | City water | Brackish water | Sea water | |

| TDS(Mg/L, PPM) | 2-10PPM | 100-1000PPM | 2000-20000PPM | 20000-40000PPM |

| Domestic Daily use | Yes | Yes/No | No | No |

| Irrigation, industry | Yes | Yes | No | No |

| Ro Material | UPVC/SUS304 | SUS304 | SUS316 | SUS-316/2507 |

| Can it use our system? | Yes, our system can convert seawater and brackish water (from underground boreholes, rivers, etc.) into fresh drinking water. Additionally, our system can transform city water into pure bottled or sachet drinking water. Furthermore, our system can also purify water into ultra-pure water for specialized industrial or medical use, etc. | |||

| 6000LPH Reverse Osmosis Technology Description |

| The KAI YUAN 6000 LPH Factory Purifier System is an advanced Brackish Water Filter Machine designed to transform brackish water into high-quality drinking water. This Industrial Drinking Water Plant Treatment Equipment is built to meet the rigorous demands of factories, commercial facilities, and agricultural applications, ensuring reliable access to purified water. Engineered for efficiency and durability, the KAI YUAN system provides an optimal solution for businesses seeking a cost-effective, high-capacity water purification system. |

| Product Advantage of the KAI YUAN 6000 LPH Brackish Water Treatment System |

1、High-Capacity Purification: Capable of processing up to 6000 liters per hour, the KAI YUAN Brackish Water Filter Machine is designed for high-demand applications, ensuring consistent and large-scale water purification. 2、Advanced Filtration Technology: Utilizing state-of-the-art Reverse Osmosis (RO) membrane technology, this system effectively removes dissolved salts, heavy metals, and other impurities commonly found in brackish water. The RO membranes are durable and deliver superior filtration performance, meeting industrial-grade water standards. 3、Durable Construction for Industrial Use: Built with premium-quality, corrosion-resistant materials like fiberglass, the KAI YUAN 6000 LPH Factory Purifier System is designed to withstand the challenging conditions of industrial environments. This ensures long-term reliability and minimal maintenance. 4、Energy-Efficient Design: This Industrial Drinking Water Plant incorporates an energy-saving design that optimizes power usage, significantly lowering operational costs. Efficient energy consumption also reduces the environmental impact of large-scale water treatment operations. 5、Fully Automated Operation: Equipped with an intuitive control panel, this Brackish Water Treatment Equipment offers automated monitoring of critical performance indicators such as flow rate, pressure, and water quality. Operators can adjust system settings with ease, ensuring optimal purification efficiency. |

| Our Service: A team of skilled engineers is committed to developing, manufacturing, installing, and debugging the equipment, with international sales available for contact at any time. We maintain strict quality control—our products are certified by CE and SGS—and also provide attentive customer service through our hotline. Meanwhile, professional engineers can provide satisfactory plans based on customer requirements; for example, OEM/ODM services are available. We have more than 20 engineers who provide various treatment processes according to the customer's raw water quality and output water requirements. All of them have over 8 years of experience, and our pipe connection technology achieves high medical standards. They can also assist with the installation of our machines globally if customers need it. In other words, we are a 100% OEM/ODM professional team, and we provide free lifetime technical support for you. Our advantages: A. Stable quality, no change in suppliers for over 16 years; B. Price is ideal and remains fixed; customers trust us; C. Fast delivery and high efficiency; we prioritize timeliness for our customers' convenience; D. Professional team; tell us your needs, and we will quickly provide a suitable solution for you. |

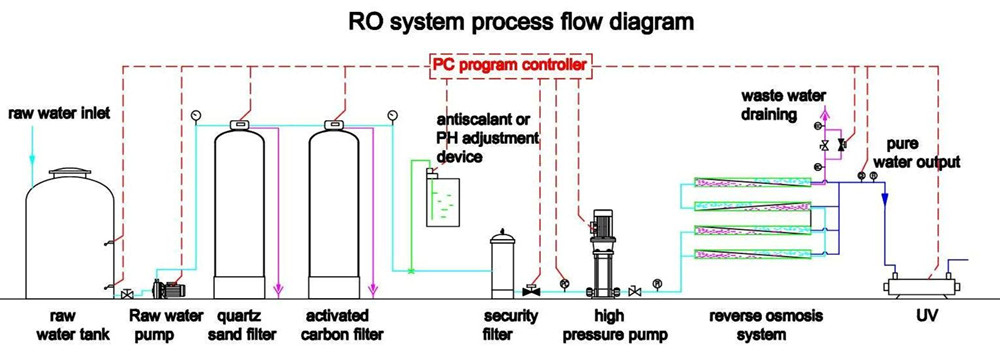

Flow Process

| Part 1: Water Pumps---Raw Water Pumps, CIP washing pumps and High Pressure Pumps 1.Brand: CNP , Grundfos or Danfoss. 2.Material: Can be SUS-304 for fresh water purification, or SUS-316 for salty/brackish water desalination. 3.Name and Function: Raw water pump to provide pressure for pre-treatment part, High pressure pump to provide pressure for Ro membranes, CIP Washing pump for membranes maintenance. |

Part 2-1: Pre-treatment Filter Tanks--Multi-media filter, Activated carbon filter and Iron(boron, arsenic) removal Part2-2: Rinse and Backwash Flushing valves for filter tanks--Manual and automatic one for options. 1.Brand: China Rongxintai tanks, and RUNXIN Valves. 2. Material: Can be fiberglass or SUS-304 or SUS-316 |  |

|

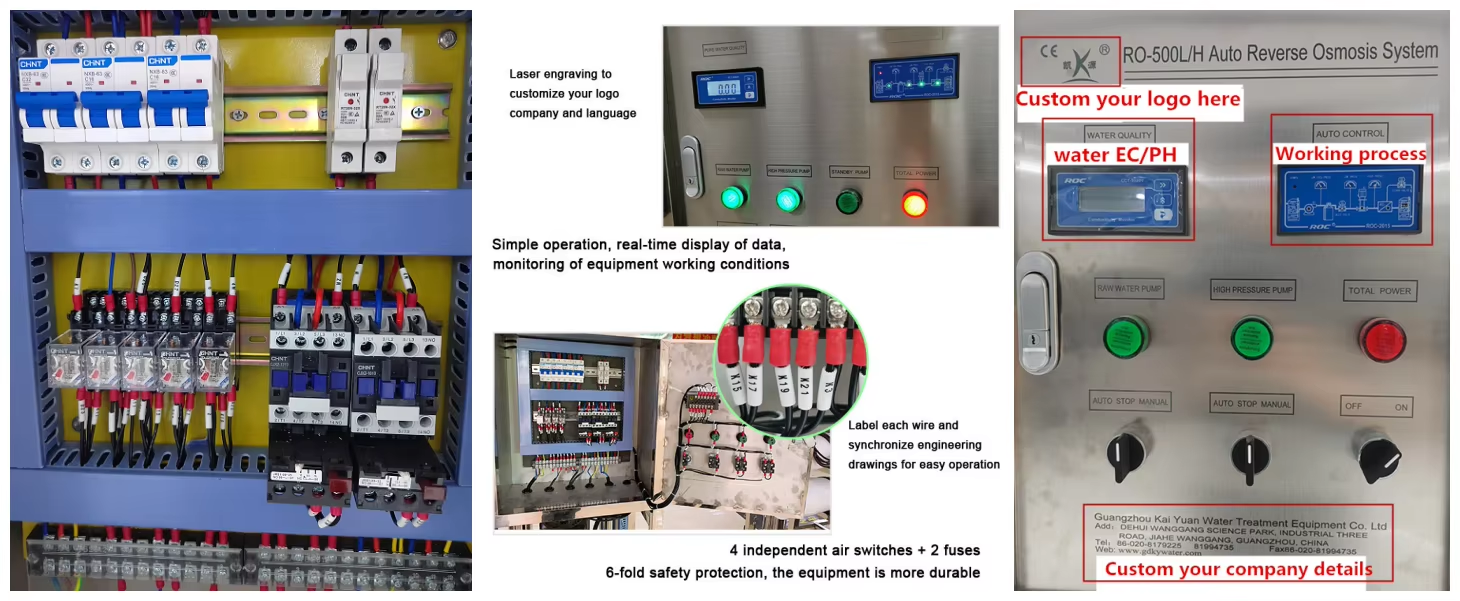

Part 3-1: PC panel--Anti-rusty Steel material control bo For this section, the outside of PC panel, we can see the online conductivity meter and PH online data for raw water and Ro output water. Then you can also see the whole system working process diagram. Besides, we can customize your company logo and other details on the electric box. The inner electricity side, we have frequency inverter(if necessary), AC contactors, Thermal relay, Fuse box, Air switch, Indicator light, Knob switch, Power switch, Intermediate relay, Sound and light alarm, electrical miscellaneous items, etc. But if you want PLC control box, please check details as followed. |

|

Part 3-2: PLC panel--The left photo is inductive operating panel For this section, we can customize your company logo and other details outside the electric box. The inner electricity side, we have SIEMENS program control, Frequency inverter(if necessary), AC contactors, Thermal relay, Fuse box, Air switch, Indicator light, Knob switch, Power switch, Intermediate relay, Sound and light alarm, electrical miscellaneous items, etc. |

| Part 4: Membrane protection system(Anti-scale dosing) and membrane maintenance system(CIP washing) 1.Anti-scale dosing system(SEKO Italy brand metering pump and yellow PE material tank) to protect the Ro membranes being blocked shortly by using anti-scalant, which will be fully automatically. 2.CIP washing system(CNP washing pump and PE washing tank) to maintain the Ro membranes by adding NaOH and HCL after using about half year, and the membrane are blocked. |

Company Introduction

FAQ

Q: What is the capacity of the KAI YUAN 6000 LPH Brackish Water Filter Machine?

A: The system processes up to 6000 liters per hour, providing a daily output of up to 120,000 liters, ideal for industrial and commercial uses.

Q: What impurities can this machine remove from brackish water?

A: Using advanced Reverse Osmosis (RO) technology, this machine effectively removes salts, heavy metals, organic compounds, and other impurities, producing high-quality drinking water.

Q: Can this system be customized?

A: Yes, it can be tailored with additional filtration stages, pre-treatment options, and post-treatment modules to meet specific needs.

Q: What materials are used in the system?

A: Constructed with Fiberglass, for brackish water equipment, FRP material is more corrosion-resistant

Q: What maintenance is required?

A: The system has an automated control panel for easy monitoring. Regular maintenance includes replacing filters and membranes, with full support provided by the KAI YUAN team.