- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

KYEDI-250L/H

KAIYUAN

Product Description

Product Description:

Electrodeionization (EDI) is a continuous process that utilizes an applied current to remove ionized and ionizable species from a water source while continuously regenerating the ion exchange media.

Ions are transferred to concentrate chambers by the use of cationic and anionic semi-permeable membranes and flushed out of the module through a continuous waste stream. Dilute product water moves through the dilute chamber and out of the module. An on-skid rectifier will apply a voltage to remove dissolved impurities.

EDI is used for high purity and ultrapure applications, including boiler feed makeup water, where required product resistivity is ≥ 5MΩ. EDI typically follows a single or double pass reverse osmosis system (RO).

Advantages of the EDI water system as opposed to the conventional systems of ion exchange resin:

·Produce high quality of ultrapure water for laboratory water 10.0-18.0 MΩ.cm in constant flow

·Cost effective operation and maintenance in EDI equipment with double stage RO system. Simple and continuous produce ultrapure water instead of batch cycle.

· Non pollution. Safety and reliability. Chemical free (used electricity instead of chemical for regeneration) and environmentally safe.

· Reduce water hardness by Ion Exchange Water Softener machine.

· SUS304 material, no sanitary dead corners, water purer and cleaner

· Required small footprint operation.

Applications:

SUS304 250L/H Double stage RO system plus water softener with EDI equipment, reduce hardness of the water, is suitable for pharmaceutical application, medical industry, power and energy industry, boiler application…etc, which required product resistivity is ≥ 5MΩ.

Technical Parameters

Model | KYEDI-250L |

Production capacity | 250 Liter/hour |

| Power supply | AC 380 50HZ (Customized) |

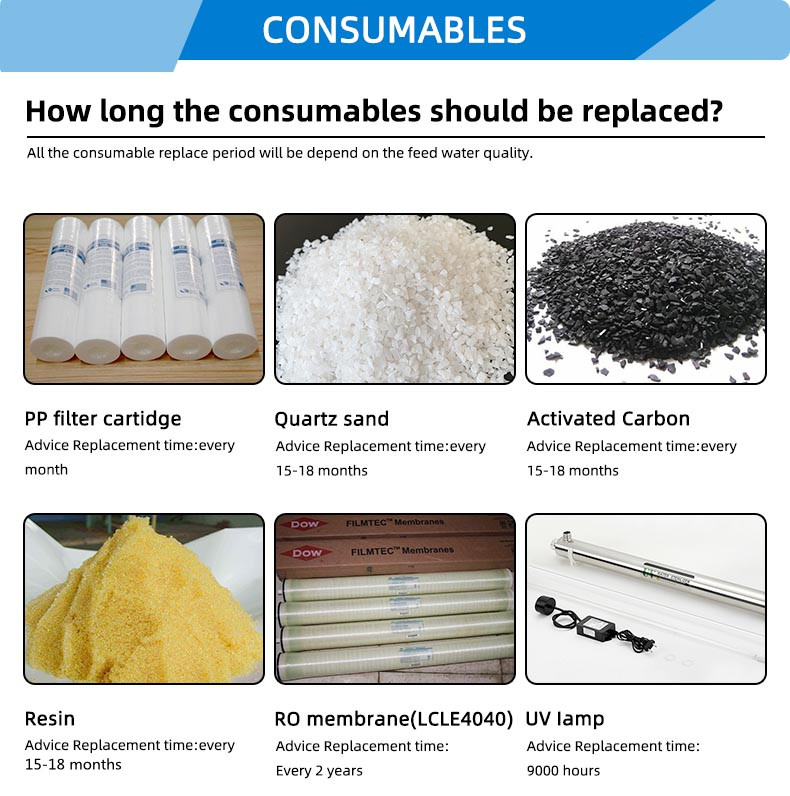

Quartz sand filter, activated carbon fitler | SUS304 material ; Automatic control valve |

| Weight | 800KG |

| MOQ | 1 set/shipment |

Working process:

Function of every part:

1.Raw water pump | provide the pressure to quartz sand filter/active carbon filter/ water softener |

| 2.Quartz Sand filter | get rid of turbidity, suspended matter |

| 3.Active Carbon filter | remove the color, free chloride, organic matter, harmful matter, ect. |

| 4.Water Softener filter | exchange "ions" of calcium and magnesium with the most common and easiest method |

| 5.Security filter | prevent large particles into RO membrane, accuracy is 5um |

| 6.High pressure pump | provide the high pressure to RO membrane |

| 7.RO system | main part of the plant. The RO membrane's desalting rate can reach 97% and above, removing over 99% ion |

| 8.EDI system | utilizes an applied current to remove ionized and ionizable species from a water source while continuously regenerating the ion exchange media |

Product Pictures: